With the continuous development of plastic production industry, need to be applied to meet their production requirements of the feeding equipment, the central feeding system in addition to plastic molding operation to ensure the efficiency and stability of the entire system can prevent the blocking phenomenon, for the production On-site, the central feed system will be raw materials and dry barrel completely separated from the scene management, saving space. Xiaobian to introduce the following details of the plastic production industry, central feed system, what are the benefits?

The benefits of using a central feed system for the plastics industry are:

First, the central feeding system Unique centralized dust recovery system, clean up more convenient, environmental protection effect is to achieve 100,000 clean room operating standards, and reduce noise, and ultimately unmanned plastic production workshop to enhance the corporate image .

Second, the central feeding system can be designed according to the actual needs of the professional solutions that can be used by different users, different plant characteristics, different requirements of raw materials to meet the major plastic production industry, the feeding requirements, Thus enhancing the supply of plastic production workshop use, its production planning has a significant role.

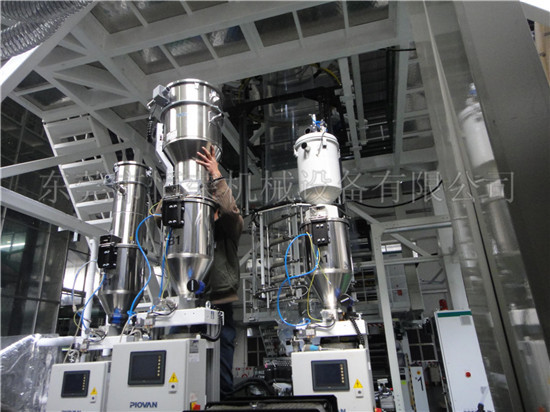

Third, the central feeding system can automatically feed a variety of raw materials to any room more than any injection molding equipment, which can include raw materials, drying, color processing, and the proportion of crushed recycled materials utilization, and to meet the non-stop The production needs, and thus the efficiency of plastic production workshop has great help.

Fourth, the use of central feeding approach, corresponding to reduce a lot of stand-alone equipment, it saves energy and reduce maintenance costs. In addition, the central feed system is easy to operate, requiring only a few people to control the entire injection molding plant's supply requirements, as well as reducing the raw material strip and associated auxiliary equipment next to the injection molding machine, improving space utilization, Good to avoid the plastic production workshop energy loss.